services

As a custom manufacturer of high volume precision machined parts Lusk Quality Machine Products is fully equipped to serve you. Our service capabilities include CNC milling, precision turning, and a complete range of secondary operations and outside processes like: passivating, heat treating, plating, soldering, and more. Registered to ISO9001 since 2003; whatever your needs, all of us at Lusk Quality Machine Products welcome the opportunity to put our expertise and superior craftsmanship to work for you.

CNC Machining Services

CNC Machining Services

CNC Machining Services

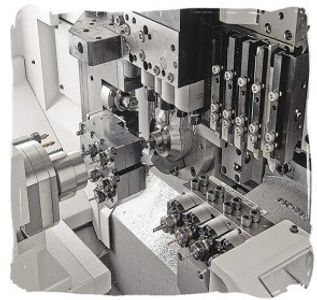

With 8 axis machines and equipped with live tooling and pallet changers, your complex parts can come off the machine complete. Efficiency that produces your parts quicker and less expensive than the competition.

Swiss CNC Machining

CNC Machining Services

CNC Machining Services

Swiss machining offers the benefit of milling products combined with the benefits of turning. Lusk Quality Machine Products offers competitive pricing for Swiss jobs and can complete your project from concept to creation.

Screw Machine: Single Spindle

Screw Machine Services: Multi-Spindle

Screw Machine Services: Multi-Spindle

With over 30 years’ experience in screw machining, our single spindle Brown & Sharpe machines are able to produce a variety of products for a wide range of markets. Our machines are suited to run jobs from ½” diameter to 2-3/8” diameter capacity.

Screw Machine Services: Multi-Spindle

Screw Machine Services: Multi-Spindle

Screw Machine Services: Multi-Spindle

Multi spindle screw machines are the backbone of our business. Our machines have produced components that end up in everything from toys and airbags to plumbing and computer servers

Secondary Operations

Outside Process Partners

Secondary Operations

In order to produce quality precision parts, quality machines and techniques are developed. LQMP uses a wide range of secondary operations machines to finish parts to customer requirements.

Secondary operations offered by LQMP include: Broaching, Sawing, Drilling, Vibrahone and Assembly.

Engineering/Tooling

Outside Process Partners

Secondary Operations

Our dedication as a custom manufacturer, we have a in house Engineering and Tooling Department with the ability to create any needed tooling for each project.

Outside Process Partners

Outside Process Partners

Outside Process Partners

The ability to produce successfully does not happen by chance. We partner with only the best in outside processes that share LQMPs same commitment to quality.